Smart craftsmanship

missing translation: fa.article-intro.reading-time – Copy: AUDI AG ― Photo: AUDI AG ― Video: AUDI AG – 05/02/2023

missing translation: fa.article-intro.reading-time – Copy: AUDI AG ― Photo: AUDI AG ― Video: AUDI AG – 05/02/2023

Marrying the body, battery, electric motors and suspension to create the Audi e-tron GT quattro. A workpiece carrier positions the components under the body with millimeter precision.

Marrying the body, battery, electric motors and suspension to create the Audi e-tron GT quattro. A workpiece carrier positions the components under the body with millimeter precision.

As an employee carefully runs her gloved hand over the exterior paintwork of the fully electric Audi e-tron GT quattro, her gaze follows the movement. The vehicle is illuminated with a special light. Eagle-eyed Audi experts would immediately spot any imperfections during the rigorous quality control process. Paintwork, joints and gaps are put under the microscope one final time. It’s a last chance to make fine adjustments. Once the Audi e-tron GT quattro car has passed through this final station — the finishing check — it’s ready to leave the Böllinger Höfe premises.

Before getting to this point, production models pass through numerous stations. The Böllinger Höfe plant at the Audi site in Neckarsulm employs innovative, purpose-built technologies to manufacture the fully electric gran turismo. The finishing touches are always done by hand. Wolfgang Schanz, head of production at Audi Böllinger Höfe, explains, “Producing the Audi e-tron GT quattro and its body in particular is a highly automated process. Nevertheless, handiwork is part of every assembly line cycle. The truth is that building a car still calls for craftsmanship. Our colleagues perform this work with great attention to detail.” Experience is another key factor. “We’ve carried over all the handicraft skills built up in manufacturing the Audi R8. What’s more, the same passion our employees invested in building the Audi R8 is now being poured into the Audi e-tron GT quattro. Right from the concept phase, the Böllinger Höfe plant was designed as a small-series production facility with innovative and flexible production processes,” says the production manager. Ideal conditions for manufacturing the Audi e-tron GT quattro.

In order to accommodate vehicle production for both models at one location, the flexible small-series facility was upgraded and expanded. While retaining the strengths of the Neckarsulm-based Audi facility, integrating the Audi e-tron GT quattro has entailed adding new areas of expertise relating to electrification, automation and digitalization.

“Building a car still calls for craftsmanship – with great attention to detail.

Wolfgang Schanz, head of production at Audi Böllinger Höfe

Paintwork quality control during the final finishing check.

Paintwork quality control during the final finishing check.

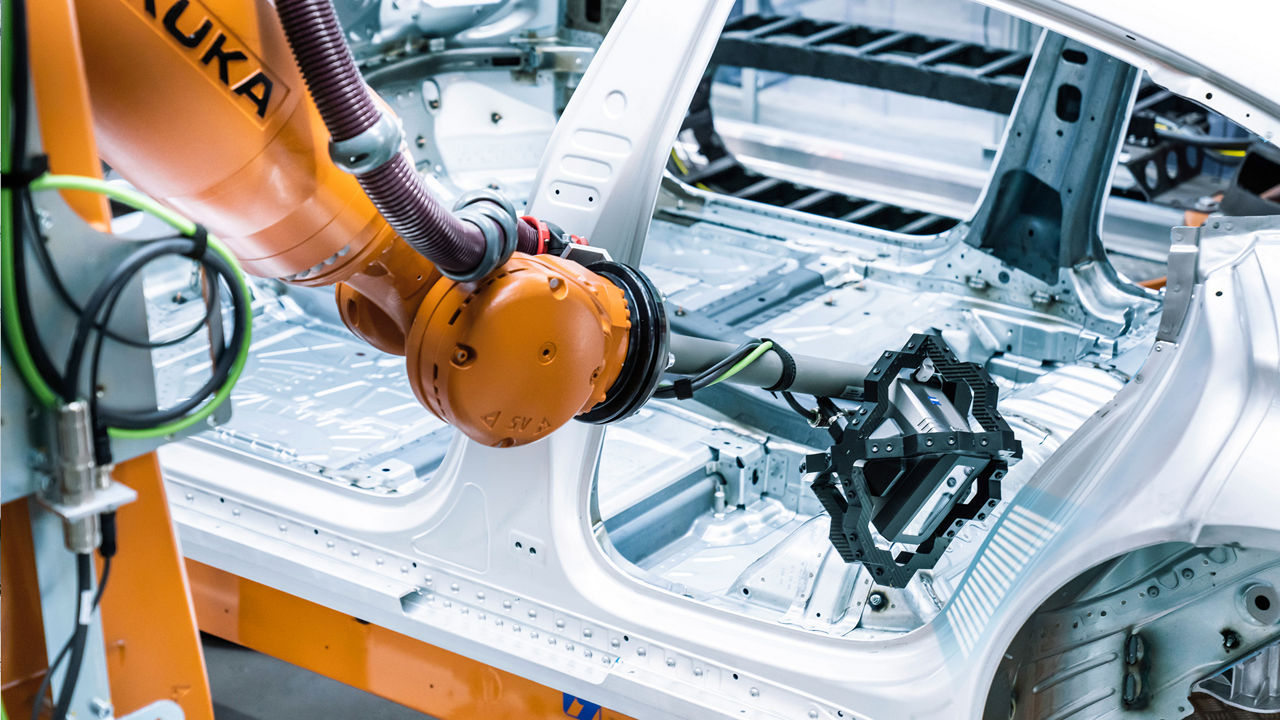

It goes without saying that striving to produce high-quality, precision-engineered vehicles is a top priority at Böllinger Höfe. Every process and every flick of the wrist is performed to this end. The body shop is just one example of the perfectly symbiotic relationship between craftsmanship and cutting-edge technology. A number of different joining methods, ranging from resistance spot welding through screws to rivets and bonding, come into play here. At the heart of the shop is a large clamping and attachment system, known as the two-way framer.

“A framer is used to add large assembly groups to the body, ultimately defining its geometry. Traditionally, two such framers, set up as successive assembly lines, are necessary for body construction. At Böllinger Höfe, we have succeeded in combining these steps into a single station that each car body passes through twice. That’s why it has been dubbed the two-way framer,” explains Christoph Steinbauer, head of the body shop. “On the first pass, the inner side panels are attached; the outer ones on the second. Ten robots with 32 tools are on the job, completing the steps required to join the panels to the car body. They automatically switch tools between the two passes and even during the work steps.”

The heart of the body shop the two-way framer.

The heart of the body shop the two-way framer.

Another new station is dedicated to correlation-free measuring. Two robot-guided optical measuring heads check the exact dimensional accuracy of the body. In investigating each car body, they check 350 measuring points. At each point, a blue stripe pattern is simultaneously created and scanned, before the robotic arm proceeds to the next one. In this way, they work systematically from one spot to the next. Room cameras detect and constantly compare the exact location of the measuring heads. By generating volumes of ultra-precise data, this process makes it possible to respond rapidly to even the tiniest deviation. In addition to high-tech systems, the body assembly line includes two manual stations. Here, machines pass the baton to humans who weld with great precision by hand. The employees at this station benefit from the experience gained working on the Audi R8. Welders who have spent years crafting the sports car with a V10 combustion engine entirely by hand are now performing high-precision fusion welds, for instance, on the Audi e-tron GT quattro.

Correlation-free measuring is performed on the assembly line with the utmost precision. 350 measuring points are checked. At each point, a blue stripe pattern is simultaneously created and scanned.

Correlation-free measuring is performed on the assembly line with the utmost precision. 350 measuring points are checked. At each point, a blue stripe pattern is simultaneously created and scanned.

After the body assembly line, the car-in-progress moves on to the mounting stage. Body manufacturers mount the car’s fenders, doors, as well as the engine hood and tailgate. This step entails focusing on achieving precise, uniform gap dimensions and high-quality surfaces. Even minimal tolerances on the outer skin parts can result in deviations. This is why the job not only calls for meticulous care and attention but also is best achieved through a return to traditional craftsmanship. A trained carpenter, for instance, who has a keen eye and feel for surfaces, is part of the team. After the mounting stage is completed, the bodies are painted.

Gap dimensions are checked by hand. Even minimal tolerances can result in deviations.

Gap dimensions are checked by hand. Even minimal tolerances can result in deviations.

Freshly painted Audi e-tron GT quattro bodies are briefly stored in a high bay in the basement of Böllinger Höfe. From there, driverless transport vehicles (DTV) carry them to the assembly line on the ground floor. They find their way with the help of a navigation map that includes a digital representation of the surroundings. Two laser scanners at the front and rear sound out the surroundings, ensuring that each DTV knows its exact position at all times. Every day, the 20 smart transport vehicles cover a total distance of a good 23 kilometers and not only deliver bodies for assembly but also carry them during the first cycles and at the end of the line. To ensure an ergonomic working environment, the driverless transport vehicles can adjust their height as needed.

A unique feature of this production section is that the Audi e-tron GT quattro and Audi R8 are manufactured on the same assembly line. To coordinate the joint production process, the number of cycles has been increased from 16 to 36. The logistics experts in charge of the processes carefully choreograph everything so that the components for each model arrive in the right place at the right time and in the right sequence. To ensure production runs like clockwork, all assembly procedures were tested in advance not directly on site, but using VR technology.

A key element of assembly is the “marriage.” This is when the body of the Audi e-tron GT quattro is combined with the battery, electric motors and suspension. Resting on workpiece carriers, these major technical modules are moved within millimeters of the correct position below the body via a roller conveyor. With the help of self-positioning power screwdrivers and employees’ equally precise handiwork parts are screwed together.

DTV at work: Driverless transport vehicles have been moving car bodies through the assembly line at Böllinger Höfe since 2014.

DTV at work: Driverless transport vehicles have been moving car bodies through the assembly line at Böllinger Höfe since 2014.

“Planning of assembly sequences was done virtually for the most part.

Wolfgang Schanz, head of production at Audi Böllinger Höfe

Even though manual precision and dexterity are of primary importance in assembly, robots help out in this area, too for example, when fitting the front and rear windscreens. Humans and machines collaborate on this work step without safety barriers separating them. This is referred to as human-robot cooperation (HRC). Workers first place the window onto a fixture with automatically adjustable retainers. They then step aside while the robot applies the adhesive. Next, the employees take over again and fit the window to the body with extreme precision.

The 3D printer also makes life easier. At many stations, specially designed assembly aids help the staff work more ergonomically. Employees at the Böllinger Höfe facility who come up with good ideas for improvement don’t have far to go to put them into action. They simply take their proposal to the in-house 3D printing center. In partnership with a Berlin start-up, the Audi expert team has developed software that reduces the design time for pre-assembly jigs and fixtures by 80 percent. Usually, all that’s required is a sketch and the printed part is created in a matter of hours. This marks yet another big step forward, as Wolfgang Schanz points out: “We have established a lot of new methods, starting with the planning of assembly sequences, which was done virtually for the most part. In the body shop, we have introduced correlation-free measuring. And the assembly aids from the 3D printer that serve as customized solutions for our employees are already proving to be a great asset.”

By pairing extremely flexible, high-tech production with artisanal workmanship, the Böllinger Höfe plant makes a compelling case for enjoying the best of both worlds craftsmanship and smart factory technology.